Use Case

- Use Case 1 - Detection of Cooling Water Leaks in Semiconductor Manufacturing Equipment

- Use Case 2 - Water Leak Detection in Piping under Cleanroom Floors

- Use Case 3 - Drainage Leak Detection behind the Equipment

- Use Case 4 - Confirmation of Flood Damage at Communication Hut

- Use Case 5 - Laboratory Piping and Building Air Conditioning Water Leak Detection

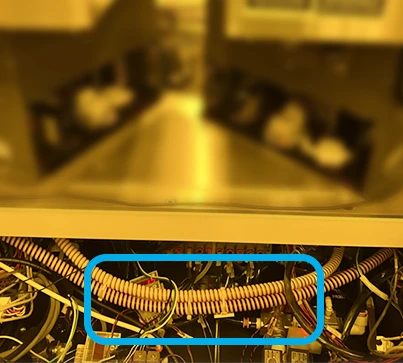

Use Case 1 - Detection of Cooling Water Leaks in Semiconductor Manufacturing Equipment

UV Equipment

(Our Semiconductor Fab)

(Our Semiconductor Fab)

- Company / Organization

- ABLIC Inc. (Our semiconductor fab)

- Background

- The device is equipped with a wired leak sensor, but detection timing is slow, so water leaks need to be detected much earlier.

- Reason for Selection

- - No wiring required

- - Retrofittable design

- Results / Benefits

- - Now possible to detect leaks before damage becomes significant.

- - Early leak detection minimizes equipment downtime.

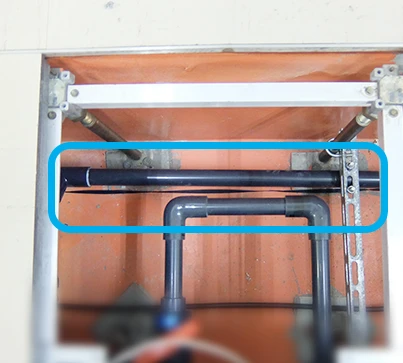

Use Case 2 - Water Leak Detection in Piping under Cleanroom Floors

for Cleanrooms

(Our Semiconductor Fab)

for Cleanrooms

(Our Semiconductor Fab)

- Company / Organization

- ABLIC Inc. (Our semiconductor fab)

- Background

- Leaks in piping installed in areas normally out of sight, such as beneath gratings or under floors within cleanrooms, can lead to delayed detection.

- Reason for Selection

- - No wiring required

- - Retrofittable design

- Results / Benefits

- - Leaks can now be detected early at any time, even when unattended.

- - Early detection enables response before leak damage escalates.

- Leak Detection Notification Method

- Email notification

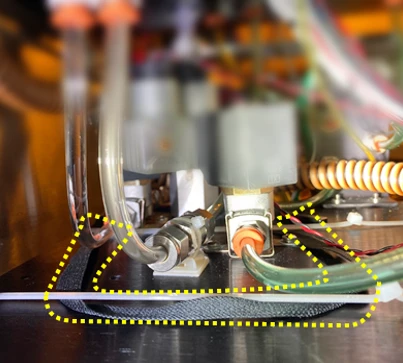

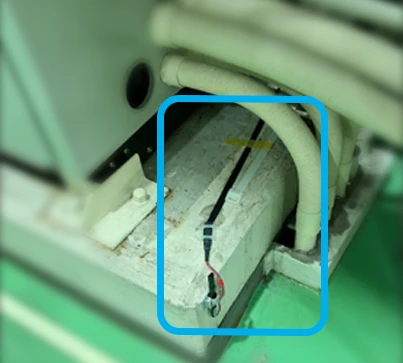

Use Case 3 - Drainage Leak Detection behind the Equipment

(Our Semiconductor Fab)

(Our Semiconductor Fab)

- Company / Organization

- ABLIC Inc. (Our semiconductor fab)

- Background

- In the unlikely event that drainage leaks from behind the equipment, delayed detection could result in damage occurring both inside and outside the factory.

- Reason for Selection

- - No wiring required

- - Retrofittable design

- Results / Benefits

- - Detects leaks behind equipment inaccessible to personnel, minimizing damage.

- - Adoption of a tower light system enables notification to nearby workers.

- Leak Detection Notification Method

- Tower light notification

Use Case 4 - Confirmation of Flood Damage at Communication Hut

- Company / Organization

NTT EAST, Inc.- Background

- Manual inspections are being conducted to assess flood damage at regional communication hut, creating challenges in terms of safety and cost.

- Reason for Selection

- - No wiring required

- - Retrofittable design

- Results / Benefits

- - Leaks can now be detected at an early stage, enabling initial response before flood damage occurs.

- - It ensures the safety of patrol personnel and has also led to a reduction in staffing. » See related topics.

- Leak Detection Notification Method

- Email notification

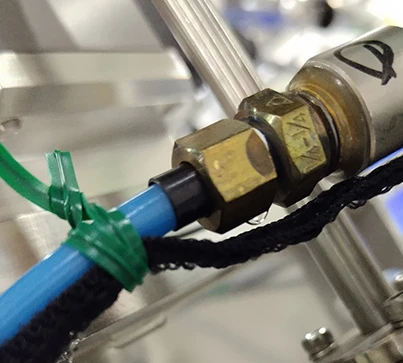

Use Case 5 - Laboratory Piping and Building Air Conditioning Water Leak Detection

- Company / Organization

UVSOR, Institute for Molecular Science- Background

- - Drop-level water leakage has occurred from the experimental pipe, potentially adversely affecting the experimental equipment.

- - HVAC is aging and may leak water, raising concerns about potential impact on surrounding equipment.

- Reason for Selection

- - No wiring required

- - Retrofittable design

- Results / Benefits

- - Early detection of leaks is now possible, minimizing damage to the equipment.

- Leak Detection Notification Method

- Email notification