Table of content

1. What is a magnetic sensor?

A magnetic sensor usually refers to a sensor that converts the magnitude and variations of a magnetic field into electric signals.

Magnetic fields, as exemplified by the magnetic field of the earth (earth magnetism) or magnets are familiar yet invisible phenomena. Magnetic sensors that convert invisible magnetic fields into electric signals and into visible effects have long been the subject of research.

It started decades ago with sensors using the electromagnetic induction effect and these efforts were extended to applications of the galvanomagnetic effect, magnetoresistance effect, Josephson effect and other physical phenomena.

2. Typical magnetic sensors and their application

Today, sensors using a wide variety of physical effects have been commercialized, however, in the following we will mainly deal with the most commonly used magnetic sensor types and their applications.

a) Coils

The coil is the most classic and simple form of sensor, we will discuss here.

Although a coil cannot be used alone to directly detect a magnetic field, it can detect the variations in a magnetic field.

Bringing a magnet close to a coil will increase the magnetic flux density in the coil. The increase of magnetic flux density in the coil will also generate opposing forces in the form of induced electromotive force and induced current. When the coil stops moving, the magnetic flux density variations also stop and the induced electromotive force and induced current cease.

Observing the induced electromotive force and induced current will allow you to detect the ratio of change in magnetic flux density and its direction.

Used alone, a coil provides only limited functionality. However, when combined with other coils or magnetic materials, it can become a highly sensitive magnetic sensor.

Currently, magnetic sensors that use coils include search coils, resolvers or rotation angle sensors as well as fluxgate sensors, a type of sensor used in a broad range of applications.

b) Reed switches

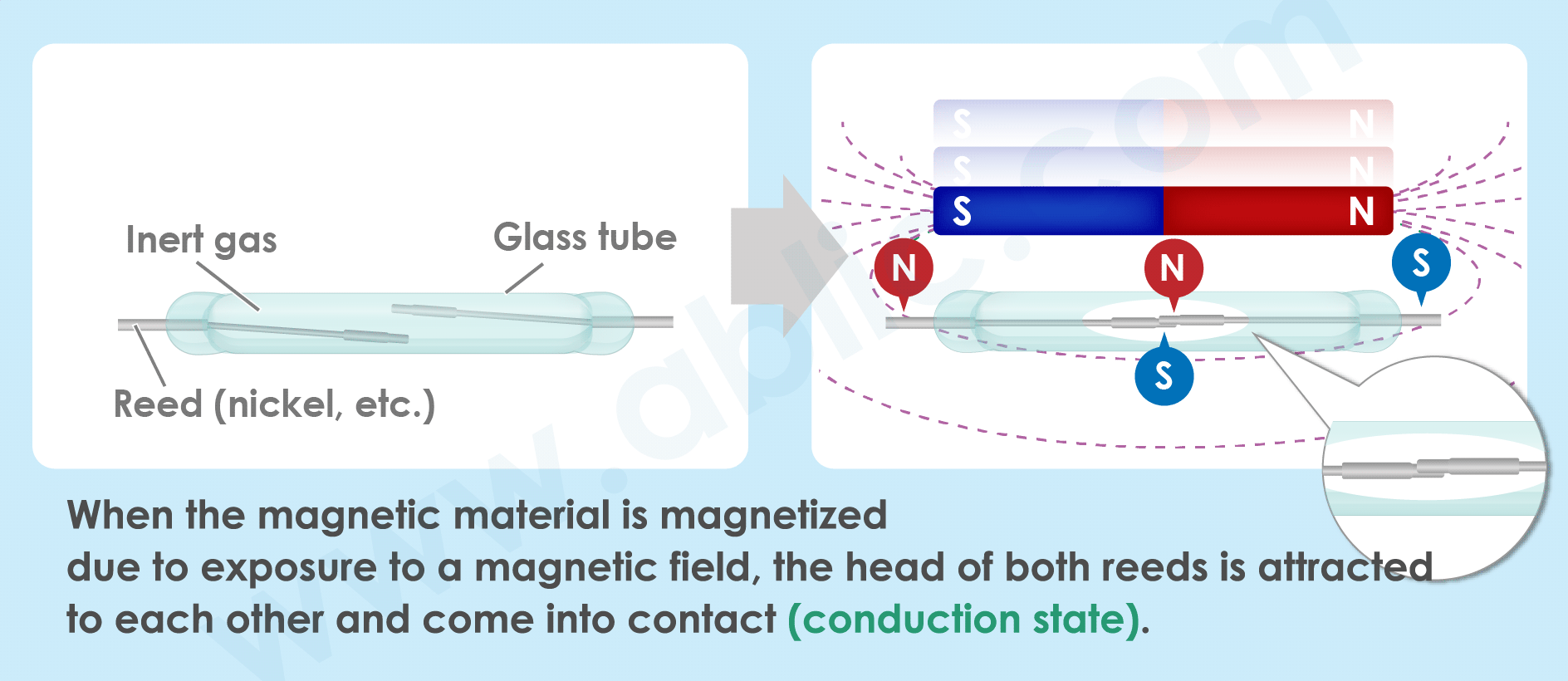

A reed switch consists of a glass tube encapsulating two reeds, the contacts, which come from the right and left ends of the tube. The reeds are made of nickel or other magnetic material and are separated by a gap. The glass tube is filled with nitrogen or other inert gas to prevent the activation (deterioration) of the contacts.

The reed switch is normally open, but when both ends of the magnetic material are exposed to a magnetic field, the magnetic material is magnetized and the contacts are attracted to each other closing the circuit (conduction state).

A reed relay, a piece of commonly used industrial equipment, can be made by combining a coil for generating a magnetic field with a reed switch.

Unlike semiconductor sensors such as MR sensor elements or Hall elements (see below), the reed switch operates without a power supply and is therefore often used in automobiles or other locations where power is difficult to supply.

c) MR sensor elements

An MR sensor element is a magnetic sensor element using the Magneto-Resistance effect (MR effect). There are a number of MR sensor types using different operating principles. The following describes the basic MR effect.

The MR effect is a phenomenon where resistance changes with changes in a magnetic field. It is an effect that occurs in magnetic materials (for example, iron, nickel or cobalt).

The MR effect requires an understanding of electron spin and how the Lorentz force operates using electron charges.

When electrons move through a ferromagnetic material (a material with a certain level of magnetism) and the spinning of the electrons fluctuates, the scattering probability (of electrons) in the magnetized material rises and falls. This is what causes the MR effect.

Electrons have two important parameters: charge and spin. They have the same negative charge, but electron spin is of two kinds: up-spin and down-spin. Electron spin was verified by an experiment in 1922 and it was confirmed that electrons exhibit electronic angular momentum and magnetic moment characteristic to electrons.

When electrons pass through conductive materials, they scatter (electron scattering). Electron scattering is a phenomenon caused by static electricity in the material that causes electrons to deviate from their normal trajectory.

Lorentz force is a force that comes into play when mobile particles (electrons) in a conductive material are exposed to a magnetic field. It affects all charged particles and does not rely on electron spin.

- AMR sensor elements

In 1856, William Thomson discovered Anisotropic Magneto-Resistance effect (AMR effect) by observing a ferromagnetic material placed in an external magnetic field environment.

When the magnetization direction in a ferromagnetic material is parallel to the current, the electron orbital becomes perpendicular to the current, which maximizes resistance. This increases the spin-dependent scattering causing electric resistance to rise.

When the magnetization direction is perpendicular to the current, the electron orbital becomes horizontal to the current reducing the spin-dependent scattering, which minimizes resistance.

The rate of change in resistance caused by the state of the magnetic field is called magnetoresistive ratio (MR ratio). The MR ratio for an AMR sensor element is about 5%. The AMR sensor element is often used in magnetic switches and rotation sensors because of its simple structure.

- GMR sensor elements

The Giant Magneto-Resistive effect (GMR effect) was independently and simultaneously discovered by Albert Fert and Peter Grünburg in 1988 by observing a non-magnetic conductive thin film structure sandwiched between two conductive ferromagnetic material layers.

The magnetization of each ferromagnetic layer is exposed to the spin-dependent scattering of electrons as they pass through the middle layer.

If the spin direction of electrons passing through the ferromagnetic layer is opposite that of the magnetization of the ferromagnetic material, the interaction effect is much weaker than when the direction of spin is parallel to magnetization.

As a result, when the direction of magnetization of the upper and lower ferromagnetic material is parallel, resistance to the current flowing along the boundary surface of the conductive material drops, while it increases if the direction of magnetization is anti-parallel.

The GMR sensor element is a magnetic sensor element applying the GMR effect. It has a magnetic sensitivity that is between two to five times greater than that of an AMR sensor element. This greater sensitivity allows a GMR sensor to detect minute changes in magnetic flux densities that were previously not possible. By replacing the coils in the read-write heads of a hard disk drive, the heads can be made more compact and more sensitive. This has vastly increased the storage densities of hard disks increasing their storage capacities.

The MR ratio of a GMR sensor element is about 20%.

Their high sensitivity makes GMR sensor elements the device of choice for magnetic heads, rotational sensors and other devices.

- TMR sensor elements

The Tunnel Magneto-Resistance effect (TMR effect) at room temperature was discovered by Professor Terunobu Miyazaki at Tohoku University in 1995. A TMR sensor element is a magnetic sensor element using the TMR effect and configured from an extremely thin nanometer level nonmagnetic insulation layer sandwiched between two ferromagnetic layers. Electrons tunnel from one ferromagnetic layer into the other via insulation layer. This is a quantum mechanical phenomenon.

Resistance decreases when the magnetization direction of the two ferromagnetic materials is parallel and increases when it is antiparallel.

The MR ratio (the rate of change in resistance depending on the state of a magnetic field) in TMR junctions can reach more than 100% in production. In lab conditions, levels upwards of 1,000% have been achieved.

Thanks to their high sensitivity, TMR sensor elements are ideal for use in hard disk magnetic heads or high sensitivity rotation angle sensors.

d) Hall elements

The Hall element is an application of the Hall Effect. The Hall effect discovered by Edwin H. Hall in 1879 proved that the Lorentz force generated a voltage at right angles to the direction of the current and magnetic field. This voltage is called a Hall voltage and according to Fleming's left hand rule the direction of the voltage changes with the direction of magnetic flux. The magnitude and direction (plus, minus) of the voltage make it possible to detect the magnitude and direction of the magnetic field (N-pole, S-pole).

The magnetic sensitivity of a Hall element is not as good as that of magnetic resistance sensor element. However, as a magnetic sensor that does not rely on magnetic material, it can be used in a ferromagnetic field environment or harsh environments and therefore finds application as a current sensor or as a variety of magnetic switches.

≫For more information , please refer to "What is Hall effect IC?"

e) SQUID

Superconducting Quantum Interference Device (SQUID) is a magnetic sensor element capable of measuring minute magnetic fields by applying the Josephson effect. SQUID, a device that combines a ring-shaped superconductor with the Josephson Junction proposed by Brian D. Josephson in 1962 is the most sensitive magnetic sensor currently available.

This sensor can detect the heart's and brain's electromagnetic fields, which are undetectable to other sensor technologies.

3. ABLIC's magnetic sensors

ABLIC now manufactures Hall effect ICs by integrating silicon Hall elements with signal processing circuits.

We can provide the ideal product to suit your application and environmental needs.

| ABLIC's magnetic sensors |

| Hall effect ICs General-use (Small, Low IDD) | General-use (Hi-Speed/Hi-Volt) ZCL | for Automotive |

Striving for a safe and livable society, ABLIC proposes and provides magnetic sensor solutions by leveraging the strengths of our sensor elements through our technology.